Choosing the Right Purlins for Your Construction Project - Key Factors to Consider

Apr 19, 2024 | by

Geometric Steels

In the realm of construction, every element plays a crucial role in ensuring the structural integrity, durability, and longevity of the building. Purlins, often overlooked but vital components of roofing systems, are no exception. Selecting the right purlins for your construction project is essential to achieving a reliable and resilient roofing structure that withstands the test of time. In this comprehensive guide, we'll explore the key factors to consider when choosing purlins for your next construction project.

1. Load-Bearing Capacity:

One of the primary considerations when selecting purlins is their load-bearing capacity. Purlins must be able to support the weight of the roofing materials as well as any additional loads such as snow, wind, or equipment. Understanding the design loads and span lengths of the roofing system is essential for determining the appropriate size and strength of the purlins.

2. Span Length:

The span length, or the distance between support points, dictates the size and spacing of the purlins. Longer spans require larger and stronger purlins to ensure structural stability and prevent excessive deflection. It's crucial to carefully evaluate the span lengths and select purlins that can adequately span the distance between supports without compromising performance.

3. Material Selection:

Purlins are available in various materials, including steel, aluminium, and wood. Each material offers unique advantages and considerations. Steel purlins are preferred for their high strength-to-weight ratio, durability, and resistance to corrosion. Aluminium purlins are lightweight and corrosion-resistant, making them suitable for environments with high humidity or salt exposure. Wood purlins may be preferred for their aesthetic appeal and ease of installation in certain applications.

4. Profile Shape:

Purlins come in different profile shapes, such as C-purlins, Z-purlins, and U-purlins. The profile shape affects the structural properties, installation method, and overall performance of the purlins. C-purlins are commonly used for roof applications, while Z-purlins are often used for wall framing. Consider the structural requirements and design preferences of the project when selecting the appropriate profile shape.

5. Connection Details:

The connection details between the purlins and the supporting structure are critical for ensuring secure and reliable attachment. Properly designed connections prevent uplift, rotation, and lateral movement of the purlins, enhancing structural stability and performance. Select appropriate fasteners, brackets, and connection methods that comply with building codes and standards.

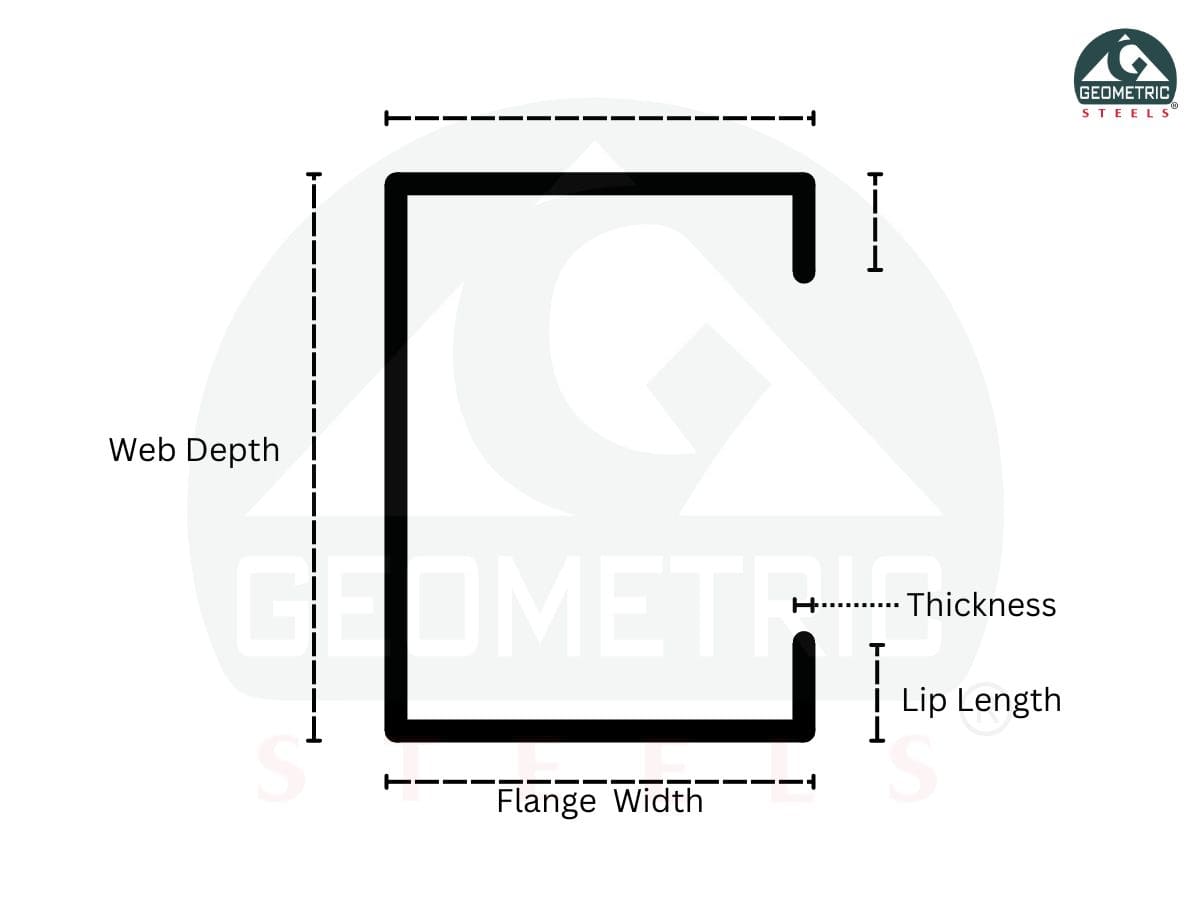

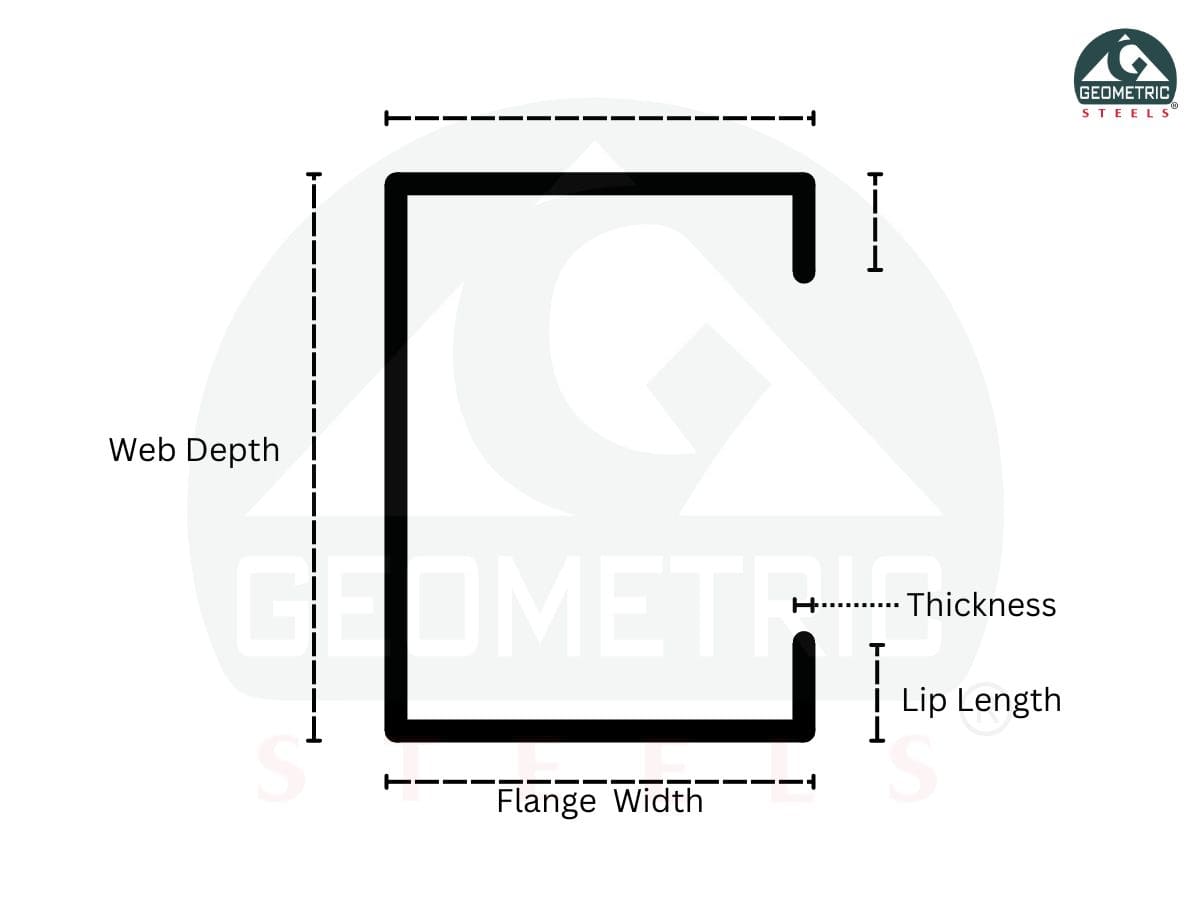

6. Web Depth, Flange Width, Lip Length, and Thickness:

These dimensional properties are crucial for determining the structural strength and stiffness of the purlins. The web depth refers to the vertical distance between the top and bottom flanges, while the flange width is the horizontal width of the flanges. The lip length refers to any extension of the flanges beyond the web, and the thickness determines the overall strength and weight of the purlins. Carefully evaluate these dimensions based on the specific loading conditions and structural requirements of the project.

7. Code Compliance:

Ensure that the selected purlins comply with relevant building codes, standards, and regulations. Building codes specify requirements for structural design, material specifications, fire resistance, and environmental factors such as wind and snow loads. Compliance with these codes ensures the safety and durability of the roofing system.

8. Cost Considerations:

Evaluate the cost-effectiveness of different purlin options, considering factors such as material costs, installation labour, maintenance requirements, and long-term durability. While initial costs are important, it's essential to consider the overall lifecycle cost of the purlins, including maintenance and replacement expenses.

9. Environmental Factors:

Consider environmental factors such as exposure to moisture, humidity, and corrosive elements when selecting purlins. Choose materials and coatings that provide adequate protection against corrosion and degradation in the project's specific environmental conditions. Additionally, consider the environmental impact of the chosen materials and opt for sustainable and eco-friendly options whenever possible.

10. Aesthetic Considerations:

In some cases, the appearance of the purlins may be a consideration, especially for exposed applications where architectural aesthetics are important. Select purlins that complement the overall design aesthetic of the building while meeting structural requirements. Consider options for finishes, coatings, and profiles that enhance the visual appeal of the roofing system.

And when it comes to reliable and high-quality purlins, Geometric Steels is a trusted name in the industry. With a commitment to excellence and innovation, Geometric Steels offers a comprehensive range of purlin solutions that meet the highest standards of quality, performance, and durability. From versatile C-purlins and Z-purlins to specialized U-purlins and custom Hat top sections, Geometric Steels provides a diverse selection of purlin products with precise web depths, flange widths, lip lengths, and thicknesses to suit various structural requirements and design preferences. Backed by years of experience and expertise, Geometric Steels is your partner in building strong, resilient, and sustainable structures that stand the test of time.